The Orangutan Ticketing Office

Describe your bamboo project and how it came about.

The Orangutan Haven (OUH) Ticketing Office is the main facility to welcome and guide visitors into the Orangutan Haven.

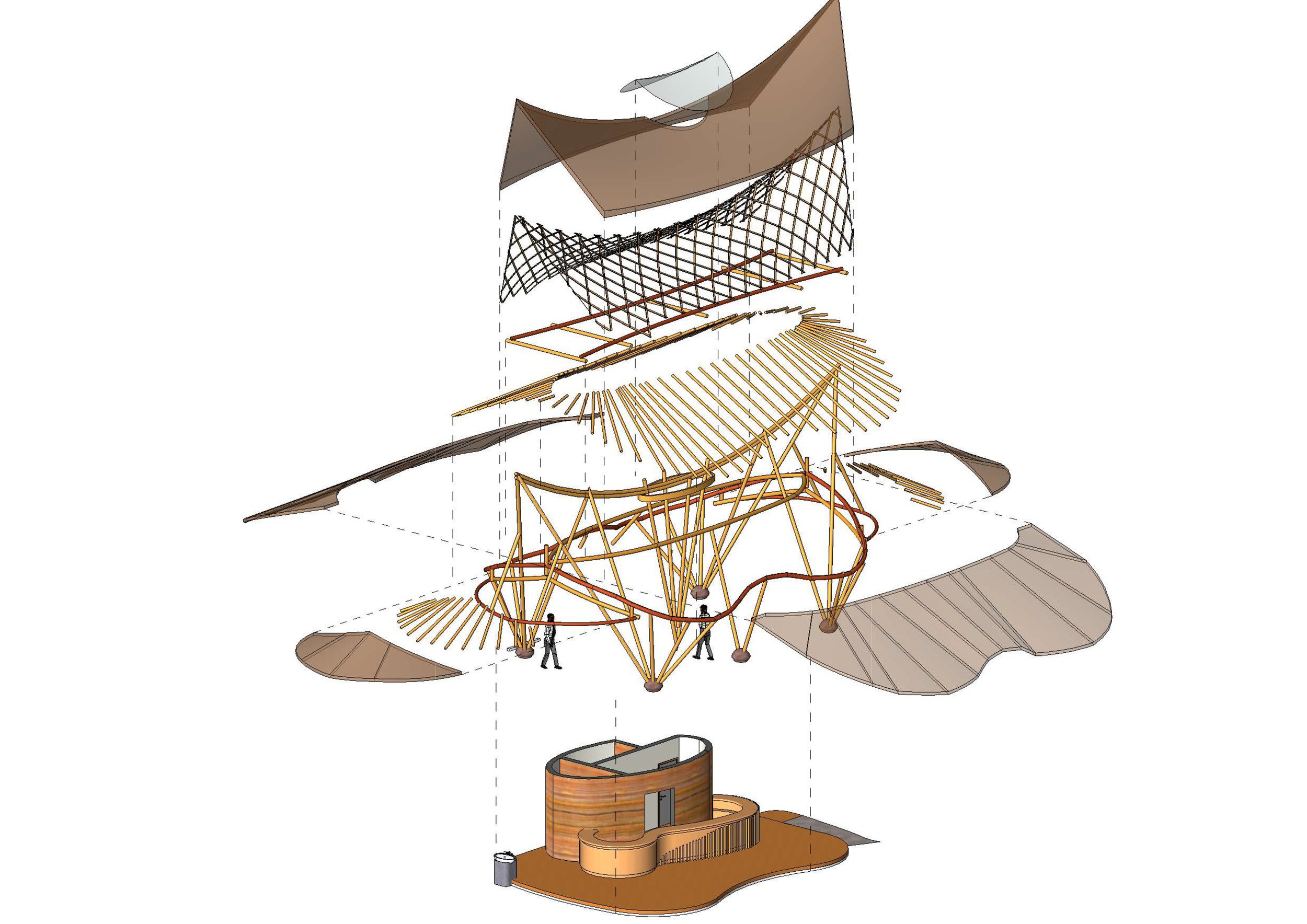

The building is located in front of the iconic Haven Bridge at the arrival area and is the first building seen when entering the Orangutan Haven site. Taking into consideration the nearby bridge structure and the dominant Karo architecture (the OUH is located in an area predominantly inhabited by the Karo ethnic group) with its triangular shape, the main structure is designed with an A-shaped profile. The lower part of the roof has an organic shape inspired by the presence of abundant taro plants on the site. Taro is a plant with wide leaves often used for rain protection. This design aligns with the secondary function of the building, which is to provide shelter during rain.

The middle walls of the building use rammed earth walls that are 100% cement-free, and the flooring is also made purely of natural materials like wood, earth and sand. This choice is in line with the vision of Orangutan Haven, which strives to use sustainable and environmentally friendly alternative materials.

Tell us about how you started in bamboo.

I am interested in bamboo since my college days and reading books about its potential. During my research on Karo architecture, I discovered that bamboo is also used in their buildings. This sparked my interest to visit the Green School in Bali and see firsthand how bamboo can be transformed into beautiful organic architecture.

I began to delve into bamboo when I started working at the Orangutan Haven. Here, I learned about bamboo harvesting, preservation techniques, storage, and on-site bamboo construction directly in the field. I also started to familiarize myself with various types of bamboo used in building construction, expanding my knowledge beyond the limited understanding of just two or three species.

Who constructs the buildings and if you can elaborate on the construction process, especially the artisans and special skills required, if any ?

The majority of the construction work is carried out by local craftsmen who have been trained at Orangutan Haven for several years. The construction process began with the creation of the ring beam using a laminated split bamboo, which serves as the main structure of the building. Once the ring beam was completed, it was lifted to the predetermined level using a pulley system. This process was something new to us, and we received assistance from Jörg Stamm in understanding the construction methods. After the ring beam is in place, bamboo columns are installed to support the ring beam and ridge beam at the top, and each joint is secured with stud bolts. At this stage, the main structure is completed, and the installation of bamboo lidi (bundles), approximately 60 meters in length, follows.

To install the bamboo lidi, we use a plumb and scaffolding to determine their position and height. The bamboo lidi, once in position, is temporarily secured to prevent any shifting. Bamboo columns are then added to support the bamboo laths. After the bamboo lidi are installed, the installation of the rafters throughout the building takes place. Once the locking mechanism of the bamboo lidi is released and opened, the bamboo lidi will maintain their original shape according to the initial design. The roofing sheets are then installed in three layers: a bottom layer, a middle layer of bitumen, and a top layer of pelupuh roofing sheets. We received assistance from a team from Asali Bali for the roofing work. After completing the structural and roofing work, we proceed with the detailing and sanding of the bamboo using 150-grit sandpaper, followed by the application of two layers coats of Ultranlasur.

What species of bamboo have you used in your bamboo journey and what are your favourites?

I have used betung bamboo, which is very strong for building structures, bamboo minyak, black bamboo, bamboo belangke, Bamboo kapur, bamboo perling, bamboo china and bamboo siam. My favourites are betung and siam bamboo because both are quite strong and definitely beautiful.

Local name Latin name

betung Dendrocalamus asper

china Bambusa multiplex

tali Gigantichloa apus

minyak /perling Bambusa vulgaris

belangke Gigantichloa pruriens

kapur Dendrocalamus hirtellus

hitam Gigantichloa atter

siam Thyrsostachys siamensis

What is the future for bamboo especially in the design and construction sector?

Bamboo is successful to create iconic buildings that are environmentally friendly and have great potential in the tourism sector, such as restaurants, cafes and hotel buildings. Bamboo can be used as a structural or architectural element in a building.

What are the main challenges in bamboo for you and how are you approaching these challenges?

The challenge I face is the lack of local workforce capable of construction work. It requires a lot of effort to explain and teach everything from scratch. Usually, I overcome this by seeking references and consulting experienced friends in bamboo design and construction.

Who or what has influenced you in your bamboo work and why?

I have seen many buildings from Ibuku Bali, Chiangmai Life, and Vo Trong Nghia. All of their buildings express organic forms with different languages of architecture, and I find them incredibly beautiful.

FACT SHEET

Name of Project : Ticketing Office

Designer: Jhon Saragih

Location: Orangutan Haven, North-Sumatra, Indonesia

Client: Orangutan Haven

Cost of bamboo construction: Total costs 35.000 USD

Bamboo species used: Betung, Tali

Bamboo builder: OUH Construction Team

Special techniques/processes : Laminated Ring Beams, Cordwood Logs for Flooring

Credits: John Saragih, Gilbert Murrer @bamboogam and Ewe Jin Low @ewejinlow