Bending Bamboo

For many working with bamboo, there is always this desire to design with the natural flowing curves of bamboo be it in furniture, sculpture or buildings. The image of bamboo culms being fanned and swayed by a gentle breeze…

Yet, not all bamboo poles grow up as curved poles, most are relatively straight, some waver and some even corkscrew as they grow. However, we often see bamboo in many successful curved applications in accessories, furniture, building components like windows/doors and integral building structures. How do produce the bamboo curves we want in our designs?

How do we ‘Bend it like Beckham’?

Bamboo Modelling Workshop at BambooU Bali 11 day Course.

If we can start off with full culm bamboo or bamboo as whole poles here is a range of methods that we can use to bend them:

1. By selection of naturally curved culms – go to a bamboo clump to select, identify as ready/mature and harvest a naturally curved pole that matches your specification. Note that naturally curved culms are rare especially in cultivated bamboo areas as they are cultivated and trained to grow vertically to avoid interweaving. Also the curved bamboo that you locate have usually more gentle and uneven less uniform curves.

2. By growing it into a curve – go to a bamboo clump, identify a shoot or young pole and over time curve-mould them with car tyres (like Brian Erickson does for his furniture) or use rope to tension them into the curve required, then when matured, harvest and process.

Oscar Hidalgo in ‘Bamboo, the Gift of the Gods’, shows us how we can ‘deform’ bamboo through natural longitudinal deformation or artificial longitudinal deformation.

There are many videos on how to shape and bend Lucky Bamboo but let us recognise that Lucky Bamboo is a dracaena and is not from the bamboo family.

3. By green drying – Harvest a green pole, place it in tension and dry it in a mould to suit the curve wanted. Note that once the pole is dry, it cannot be curved much further with this method (see later for other method to curve dry bamboo) as it would have set.

4. By soaking or steaming – this method can work well with small diameter and less dense bamboo poles but it will not be as effective on thicker and denser bamboo poles.

Straightening bamboo poles with heat - The Bamboo Master Co, Vietnam

5. By applying heat - for green newly harvested bamboo, drill small holes close to the nodes, apply butane torch or heat source and move flame in direction of bamboo growth. If there is concern of cracking, prior to applying heat, perforate diaphrams with a long steel rod and fill inside with sand to prevent splitting (I am not that familiar with this method, FYI).

The photo above is actually of the opposite process of straightening bamboo culms in James Wolf’s factory in Vietnam (our next blogpost). This I presume can be reversed ie, to heat and curve the culms instead of to straighten them.

Photo from Lucio Ventania, Cerbambu.

6. By applying heat and pressure – for dry bamboo, bend bamboo into required curve and set in place in tension. Heat nodes with a butane torch, bolt and tie two or more poles in the same curve together to create a stronger curved beam

Curved beam being prepared - Javier Diaz and Ewe Jin Low collaboration.

IG post by @bambooubali

7. By cutting notches – with dry bamboo, make v cuts or notches (maximum of 2/3rd of the diameter and preferably close to nodes). Note that much of the pole’s strength is lost through this method due to the deep sectional cuts. Combining two or more poles in the same curve will result in a stronger structural member. This is by far the most used method to curve bamboo for large diameter bamboo construction in many parts of SE Asia.

Bamboo arch supports at Panyaden School by Chiangmai Life Architects.

8. By forming curves with smaller diameter (easier to bend) poles – the work of VTN Architects and Chiangmai Life Construction with the smaller diameter thick walled bamboo found in their region shows how to combine small thinner poles to form curved members that are structural arches and portal frames and can achieve wide span buildings like domes. This is done by templating into shape and by different methods ranging from tying, bolting and adhesives, sometimes with a inner core member.

Have a look at these base references if you want further information on 1 to 8 above:

https://www.guaduabamboo.com/blog/how-to-bend-bamboo

https://www.wikihow.com/Bend-Bamboo

Bending bamboo around a coconut tree trunk - Kamsia House by Ewe Jin Low.

We can use a combination of laths, splits or round diameter rods that are formed when a full culm /pole is cut or processed into smaller units. These units can then be bound together and curved into building components.

1. By reducing thickness of the laths – and bending to curve as required

2. By applying water, heat and tension as poles above

3. By using smaller sections and joining together, either with multiple layers, or lengthening by joining sticks

4. By laminating, templating and forming with tying and/or adhesives

Here are some examples of the curved building structure/components formed by these methods:

A nursery structure at Green Camp, Bali

1. Curved Columns and members - the above structure is using bamboo splits that are coupled and bound together to create long and flexible members to support a lightweight roof material.

Round bamboo rods made into a bundle. Options for the core can be a bamboo pole or a few bamboo splits bound..

Bamboo bundle arch supports at Chiangmai Life Construction facility.

2. Arches - combining and binding together bamboo splits, rods or thin diameter bamboo allows it to be curved to create arcs and arches. With such a wide array of applications, this has opened up many design and structural variables for designers to apply.

Split ring beam being formed at Bamboo U Bali campus.

3. Beams – as with the bundling above, bamboo splits and thin diameter culms can be templated, tied or glued together to create curved and ring beams. Prefabrication of these construction components although time consuming and tedious avoids the expense and complexity of using steel, timber or concrete alternatives.

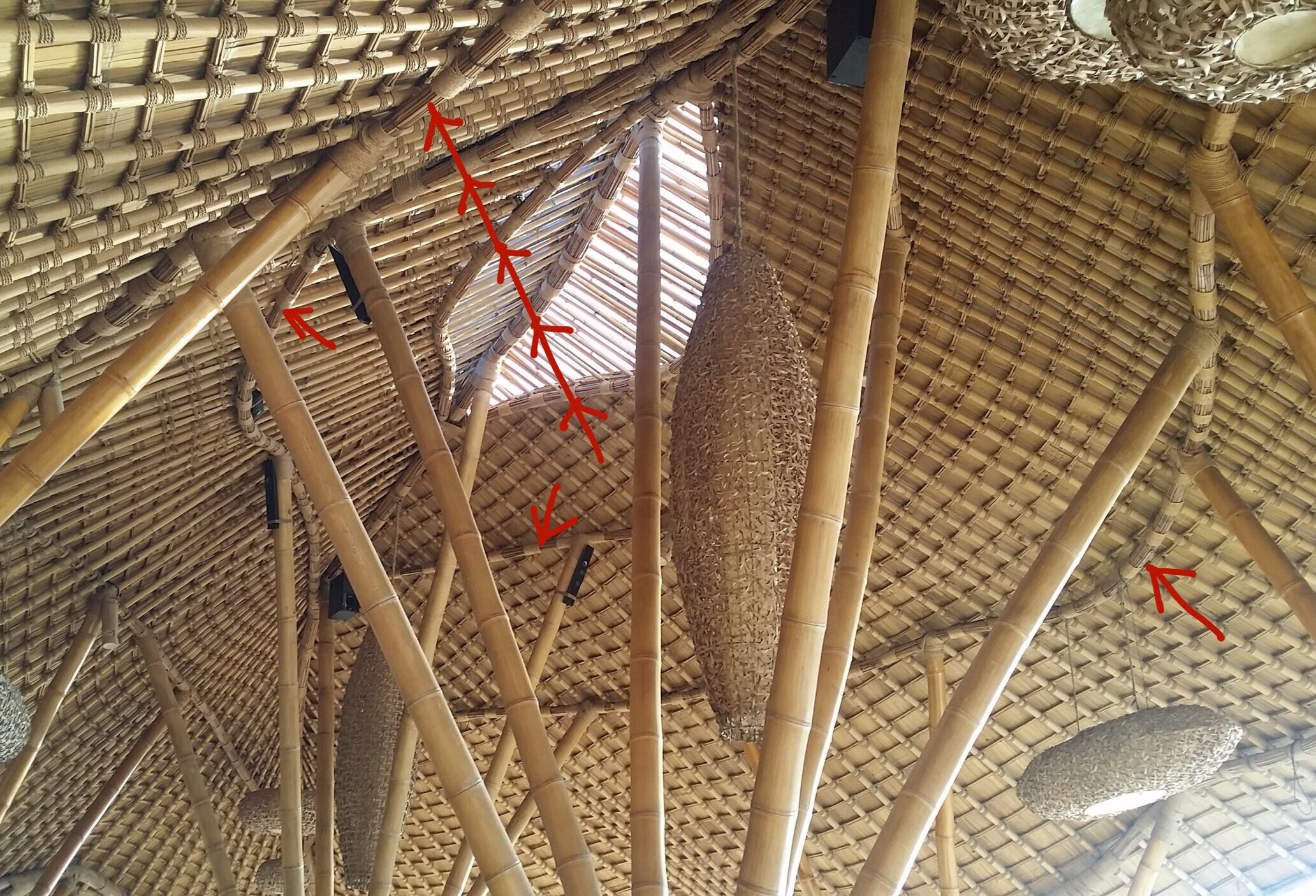

Photo of the Restaurant at Pearl of Trawangan, Bali

4. Purlins - flexible and relatively light bamboo bundles as shown above (red arrows) make sinuous forms to be achieved more simply - again this would be so much more complex and expensive in another building material. Do avoid long spans of say more than 3.6 metres to ensure that there is less sagging.

Kamsia House Ubud under construction - Ewe Jin Low, TENTEN Design.

5. Fascia edge beams - these are formed into curves on site from splits or thin diameter culms that are tied with natural rope. The photo above shows a method of tying splits that are curved to the ends of the roof rafters.

Treehouse by Ewe Jin Low, TENTEN Design.

Useful pointers when bending bamboo :

Never force bamboo into an unnaturally obtuse or tight curve– it either look totally wrong to it will break!

Curves created can be scalable but ensure that there is enough girth (by combining members) and structural strength (by looking at the spans and loads)

Always combine poles or laths together to achieve the curve and get the support strength, as above

Ensure there is adequate support when using bamboo as arches - look at combining arches with vertical pole supports.

Watch out on spanning too far with curved beams and purlins. Sagging (this is worth repeating) and even twisting can occur.

Forming circular, oval and curved ring beams from tied or laminated bamboo laths requires expertise. Seek advice from the experts who have the track record so you do not go around in circles (pardon the pun!)

Bending thick culm long span Asper for a Living Pavilion - Javier Diaz & Ewe Jin Low collaboration.

There is much more to study and innovate in this particular area of bending bamboo – I encourage you to look at it if you are ready and willing and to share the results of your work with us the bamboo community.

‘As surely as the sun rises daily, bamboo will also rise’

– Ewe Jin Low, @betterbamboobuildings